Industrial automation

Industrial automation

Empowering Industry 4.0 with High-Performance Barcode Scanning Solutions

Enabling Smart Manufacturing with Seamless Data Collection

RIOTEC’s image-based barcode scanners play a key role in supporting digital transformation and Industry 4.0 across various industrial automation applications. Whether used in production lines, automated systems, or smart manufacturing environments, our scanners enable precise and efficient data collection to improve process visibility and decision-making.

CNC Integration for Streamlined Machine Operations

Our powerful 2D barcode scan engine, such as the AI3230, can be seamlessly integrated into CNC machines to read QR codes, helping simplify complex processing and reduce manual errors.

Optimizing Conveyor Line Efficiency

RIOTEC scanners also support data collection along production conveyor lines, providing accurate, real-time information for further analysis and system optimization. This connectivity ensures that all manufacturing elements work harmoniously to achieve true automation and smart factory capabilities under the Industry 4.0 framework.

Reading DPM Codes for Industrial Precision

In manufacturing environments where traceability is critical, RIOTEC’s barcode scanners also support DPM (Direct Part Mark) decoding, enabling the reading of laser-etched or dot-peened codes directly on metal components, plastic parts, and even semiconductor chips. This capability is essential for parts tracking, quality control, and process automation—especially in industries like electronics, automotive, and aerospace where direct part marking is a standard requirement.

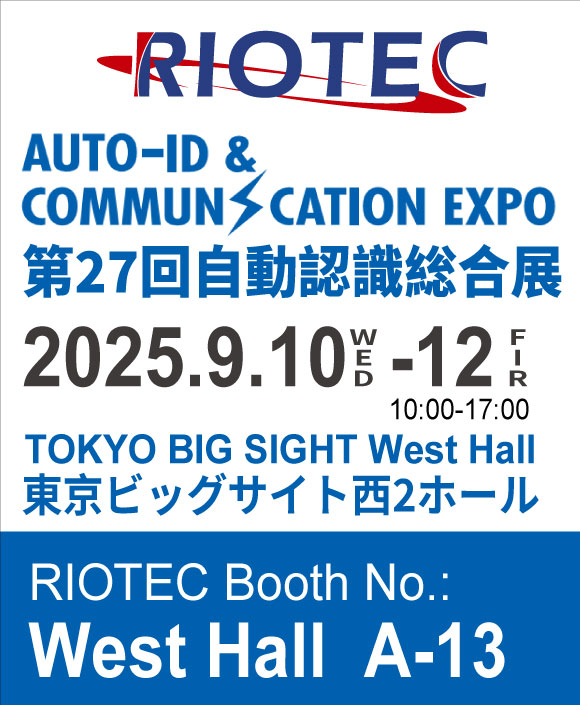

About RIOTEC

RIOTEC is a Taiwan-based manufacturer specializing in high-quality barcode scanning solutions for industrial, retail, and logistics applications. With in-house R&D and strict quality control, we offer a wide range of 1D/2D barcode scanners, scan engines, and OEM modules that are trusted by system integrators and global partners.

Looking for a barcode scanner tailored to your industrial automation needs?

Contact us today to learn how RIOTEC can help optimize your production processes with reliable, high-performance scanning solutions.

Scan Engines and Barcode Reader Modules

High-IP Fixed-mount barcode scanner